Introduction

This Light bulb investigation analysis is a part of air accident investigation from aircraft manufacture to analyse the accident that involved hard landing where no flight data is available. Therefore the alternative means is Light bulb impact analysis to identity system failures related to warning system.

CAUTION: THIS ARTICLE BY NO MEANS IT REPRESENT SPECIFIC AIRCRAFT or SPECIFIC OPERATORS. I WORK AS REPRESENTATION TO THE PARTY OF THE INVESTIGATION PRIMARILY FOR EDUCATIONAL PURPOSES.

The purpose of sharing this information is to support Air Accident investigation to obtain methodology and processes on how practically the light bulb investigation assist accident investigation

APPENDIX 1. LIGHT BULB ACCIDENT ANALYSIS

Methodology of testing : Visual & Photography, Camera Microscope (50X)

Personnel : Azzy & Setyo (Flight Operational Analyst / Test pilot)

Test date : 9 & 10 August 2005

Evaluation date: 10 s/d 11 August 2005

Introduction

This investigation was conducted to investigate high wing aircraft investigation which was crashed in the threshold of a runway with the wing fall down to passenger area injuring few occupants. At the time of crash the engine were still rotating (ground prop mark analysis) above idle RPM, however from flight path impact analysis, the estimate impact / approach angle was higher than 6 degrees glide path.

This Light bulb analysis investigation was conducted to support investigation of a an aircraft accident which at the time of investigation does not produce any Flight Data Recorder data, hence the investigation becoming very difficult. No single clue except ground marks and impact analysis from propeller ground mark that can be used for this investigations.

On other Factor that can be used by the investigator in finding probable cause in this accident particularly crash impact, is light bulb analysis, this method can be found on some reference from various sources, however the detail analysis lies on individual cases.

Objectives

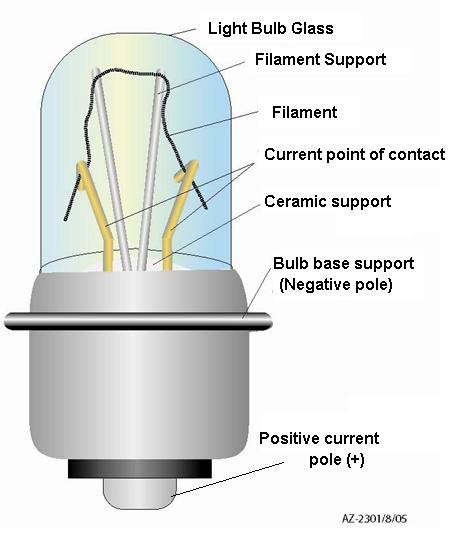

To understand the probable cause of the accident, we are trying to assess any bulb illumination at impact. Therefore it is essential to understand the terminology used

Background Analysis and Methodology of testing

This Light bulb analysis is conducted to identify an aircraft accident in specific case for aircraft which is not equipped with Flight Data Recorder.

During these research, there are various consideration made to identify the failures during impact.

- Identification of Light bulb age

- Voltage received

- Average Vibration in filament

- Quality of the bulb in case manufacturer defect exist.

This analysis is focused to Behavior of the Filament who receive inertia and gravitational forces and determination of significant elongation produced by each filament.

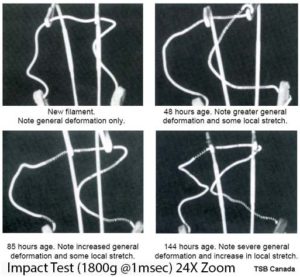

The guidance of this investigation is taken from TSB Canada documents, RTCA 169, & MIL PRF38039C.

Terminology of Impact & Gravitational forces in this investigation

Gravity

Gravity is force who act in a body in this investigation always relate to gravitational forces which is affected by earth gravitational forces, where the forces are as follows:

F = m x a

Where :

F is force in a mass

M = Mass of the matter

A = earth acceleration gravity = 9.8 m/sec2

Impact

While impact is measure of gravitational force received in a very short term, the time measured in this case is difficult to quantify, unless FDR is available. However the objective of this investigation is to determine the impact acting on the bulb which produce elongation specificaly when the light bulb is heated (Lighted)

Impact Quality

From impact point of view of the warning system (ref MIL-PRF-38039C paragraph 3.c) the warning system have to withstand shock impact of 15 G without without causing malfunction of any part of the system except indicator light source. In this case the light bulb should not broken apart causing disconnection, however may still be illuminating with maximum elongation (with reduced lifetime off course)

While from RTCA/DO-160, Section 7 testing of warning system is conducted with peak of 15 g within very short duration which is 0.011 seconds.

Determination of light bulb age

While conducting this investigation, the other team from Structure, Electrical, and avionic have not found any contributory factors.

Therfore the impact analysis is one of the method to investigate any other probability of failures particularly propeller failures (Prop oil press, pitch or reverse warnings) with other sample of bulbs (98 bulb for Central Warning system were identified) to be studied for comparative analysis

Besides those aspects, documents (Technical Log book) were also reviewed page by page to identified bulb replaced for the past 5 years.

Study of Warning System

To identify the bulb behavior, we need to identify each warning illumination time for the entire life of the bulb when installed in the aircraft as shown in table below.

When external power is applied to this aircraft, not all warning system illuminated, therefore only some light which is illuminated during preflight, including after start, taxi and before take off. Then, we are using percentage of illumination to make proportion to the aircraft block time.

| DECRIPTION | TIME | LIGHT ILLUMINATED | HRS |

| Cockpit Preparation | 6 sec | All warning during CWP Test 2-3 test per day | 24 |

| Up to Before Start | 2 min | ENG OIL PRESS, PROP OIL PRESS, WSHL HEAT, PITOT HEAT, ANTI SKID, DC GEN , LH HOTBUS, AC GEN | 250 |

| Up to After Start | 5 min | ANTI SKID | 417 |

| Up to Taxy | 7 min | WSHLD, PITOT, BETA LIGHT | 583 |

| Take Off up to Landing | 1 hour | FI SOL | 5000 |

| Landing | 2 min | BETA LIGHT | 167 |

| After Landing | 5 min | WSHLD, PITOT | 250 |

| Shutdown | 5 min | ENG OIL PRESS, PROP OIL PRESS, PITOT HEAT, ANTI SKID, DC GEN | 417 |

| At the time of accident the aircraft have accumulated about 5000 hrs of flight time. | |||

| BULB AGE | BULB DESCRIPTION |

| > 5000 Hours | FI ON |

| 800-1000 hours | MASTER WARNING AND MASTER CAUTIONS |

| 600 – 800 Hours | BETA LT |

| 500 – 600 Hours | WSHLD, PITOT HEAT |

| 200 – 500 Hours | ANTI SKID |

| 100 – 200 Hours | ENG OIL PRESS, PROP OIL PRESS, DC GEN , AC GEN |

| < 100 Hours | ENG FIRE, CHIP DETECTOR, ENG FUEL FILTER, ENG OIL FILTER |

Identification of failures due to impact

From table above, we should be able to identify the age relatively low to mid time with good bulb quality / reliability if the light was subject to impact, and to confirm the impact, there are 2 lights installed in each warning system except master warning and master cautions.

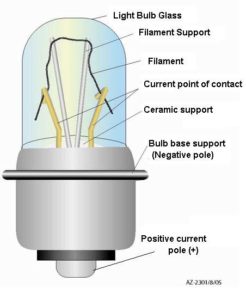

Sample of New Filament (Smooth ans straight wire) LH , New filament 700X Zoom – RH (TSB Canada)

Standard New filament from Accident Aircraft (less than 100 hours)

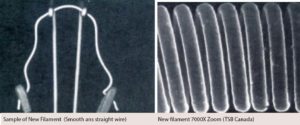

Filament 14X magnify with 144 hrs LH & Filament 14X magnify with 250 hrs RH (Normal condition with certain lifetime)

TESTED LIGHT

| DESCRIPTIONS | Tested light | Prediction of hours | Actual hours | NOTE |

| High Speed Stall ? | Stall Warning | |||

| Indication any Warning ? | Master Warning | |||

| Indication any Caution ? | Master Caution | |||

| Aby electrical deviation? | AC GEN 1 2 | |||

| Any propeller system failures? | Beta 1 2 | |||

| Auto Feather | ||||

| FI SOL 2 | ||||

| Prop Brake 2 | ||||

| Hydraulic ? | Hot Hyd Oil | |||

| HydPress 1 2 | ||||

| Engine Fire ? | Eng Fire 1 2 | |||

| Engine fuel & oil? | Eng Fuel Filter 1 2 | |||

| Eng Fuel Press 1 2 | ||||

| Eng OIl Filt 1 2 | ||||

| EngChip 1 2 | ||||

| Prop Oil Press 1 2 |

TESTED LIGHT

| DESKRIPSI | Tested light | Prediction of hours | Actual hours | NOTE |

| High Speed Stall ? | Stall Warning | |||

| Indication any Warning ? | Master Warning | |||

| Indication any Caution ? | Master Caution | |||

| Aby electrical deviation? | AC GEN 1 2 | |||

| Any propeller system failures? | Beta 1 2 | |||

| Auto Feather | ||||

| FI SOL 2 | ||||

| Prop Brake 2 | ||||

| Hydraulic ? | Hot Hyd Oil | |||

| HydPress 1 2 | ||||

| Engine Fire ? | Eng Fire 1 2 | |||

| Engine fuel & oil? | Eng Fuel Filter 1 2 | |||

| Eng Fuel Press 1 2 | ||||

| Eng OIl Filt 1 2 | ||||

| EngChip 1 2 | ||||

| Prop Oil Press 1 2 |

| Filament tested | Light installed | |

| WARNING (W) | CAUTION (C) | |

| Stall Warning 4Bulb | #1 & 2 BLEED HOT | #1 & #2 ENG FIRE DET |

| Master Caution (C) 4 Bulb | #1 & 2 DC GEN | #1& #2 ENG FUEL FLTR |

| Master Warning (W) 4 Bulb | #1 & 2 DC GEN HOT | #1 & #2 ENG OIL FLTR |

| AutoFeather ( W ) | #1 & 2 ENG FUEL PRESS | #1 & #2 FUEL COLD |

| Eng Fire 1 2 ( W ) | #1 & 2 ENG OIL PRESS | #1 & #2 FUEL LEVEL |

| Eng Fuel Press 1 2 ( W ) | AUTO FEATHER | #1 & #2 HYD PRESS |

| Prop Brake 2 ( W ) | AUTO PILOT | #1 & #2 INLET ANTI ICE |

| Prop Oil Press 2 ( W ) | BAT HOT | #1 & #2 INVERTER |

| AC GEN 1 2 ( C ) | BAT-GEN UNTIE | STBY INVERTER |

| Aux Pitot ( C ) | CABIN ALTITUDE | #1,#2 & AUX PITOT HEATING |

| Beta 1 2 ( C ) 4B | DOOR UNLOCKED | #1 & #2 WSHLD HEATING |

| Eng Chip 2 ( C ) | FLAP ASYM | #1 & #2 AC GEN |

| Eng Fuel Filt 1 2 ( C ) | GEAR UP | AILERON FWD & REAR DISC |

| Eng OIl Filt 1 2 ( C ) | TOILET SMOKE | ELEVATOR FWD & REAR DISC |

| EngChip 1 2 ( C ) | WING OVERHEAT | FLAP FAIL |

| FI SOL 2 ( C ) 4B | FRONT& REAR ANTISKID | |

| Hot Hyd Oil ( C ) | HIGH PRS DEICING | |

| HydPress 1 2 ( C ) | ICE FORM | |

NOTE:

|

WING/TAIL DEICING | |

DATA and ANALYSIS

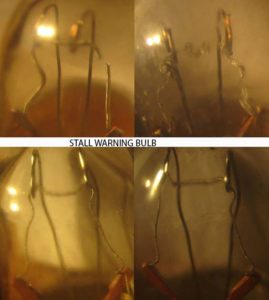

STALL WARNING (Above)

2 out of 4 Stall warning light were in broken condition, one (Lh Top) Cold condition (unlighted and non current related), while the right top one was probably due to light quality or used / relocated bulb. From both pictures, these were normal (unlighted at the time of impact) elongation were predicted at the time of stall training exercise or stall warning light test.

MASTER CAUTION(Above)

2 Master caution light out of 4 were found broken, these lights behavior is not standard / uniform, however, from two LH master caution (top LH RH) above, the light was still functioning after the picture taken and the continuity test before picture taken were satisfactory. Hence there were no master caution iluminated during impact.

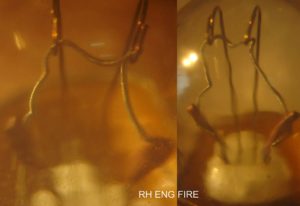

ENGINE FIRE (Above)

This indicate that the engine fire lights was not illuminated during impact although ageing were observed because of the preflight test (about 6 seconds within 5000 flight = +/- 30000 sec)

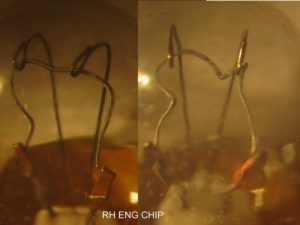

ENGINE CHIP

This indicator shown that if the oil from the engine detecting magnetic particles or microscopic debris, there is no evidence of elongation during impact during , both lights indicate ageing, however, this lights never been lighted except during preflight test, therefore there are several occasion that this light was on for quite prolonged period and repeatedly.

CONCLUSIONS

From this evaluation, there was no evidence that any predicted or expected light illuminated during impact, therefore technically there was no engine failures or aircraft system that contribute to the accident.

RECOMMENDATIONS

Although there are no direct contributory factors, however, the prolonged illumination of chips detectors need to be included in one of the investigations findings that there were several cases that the engine oil chip detector light was prologed illuminated with the probable cause of incorrect timing of oil change or oil cleanliness.

REFERENCES:

- RTCA/DO-160

- MIL-PRF-38039C (10 March 1980) Performance Specification, System, Illuminated, Warning, Caution and Advisory General Specification

- “A Guide to Light Bulb Analysis In Support of Aircraft Accident Investigation, Rev Feb 1991 by M.R. Poole & M. Vermij. Transportation Safety Board of Canada (formerly Canadian Aviation Safety Board).